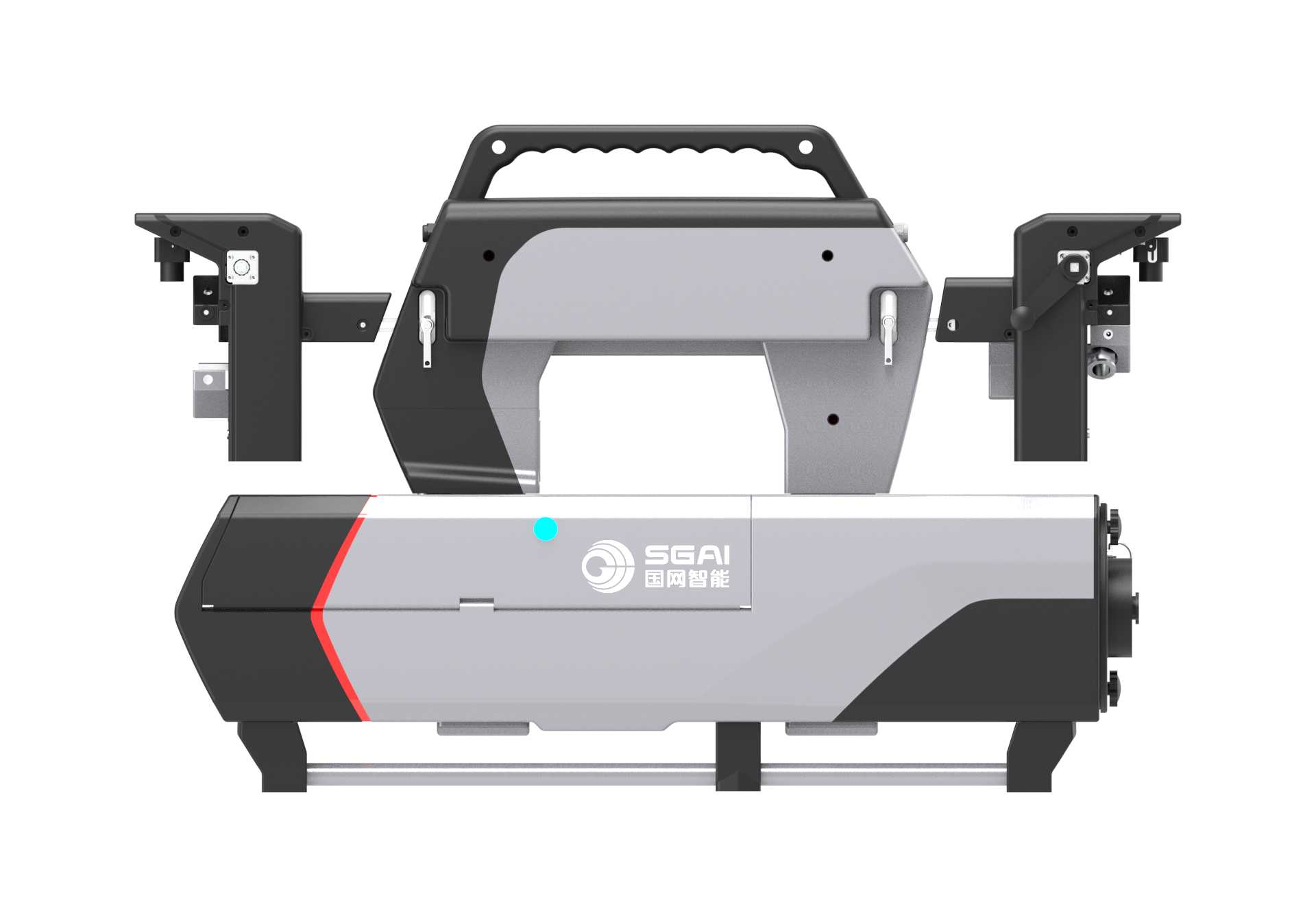

Modular cable wrapping robot

Brand Name:国网智能科技股份有限公司

Design Company Name:国网智能科技股份有限公司

Nationality / Region:China

Entry ID:2023-05-1169592

Entry Category:Product_Group

Categories:Manufacturing Equipment

Introduction

China's overall electricity consumption and distribution network scale rank first in the world, but there is still a certain gap in the reliability of distribution network power supply compared to developed countries. As of December 2021, the company has scheduled a power outage of 2.36 hours per household, accounting for 52.8% of the total. The proportion of distribution network failures and power outages caused by external damage, foreign object short circuits, and natural weather accounts for 47.2% of the total power outages. Common problems include abnormal contact with branches, crossing over fish ponds and reservoirs, being too close to residential buildings, and bird nests. Insulating and covering bare wires can effectively improve the occurrence of distribution network faults and power outages. According to statistics from the same period, the length of 6-20kV distribution lines in China is 4.372 million kilometers, and the insulation cable utilization rate is only 19.7%. Improving the insulation cable utilization rate provides a strong guarantee for the stable operation of the power grid and the safety of residential electricity consumption. The existing insulation coating robots in the market usually adopt an integrated design, which only has the function of coating coating during actual use, and cannot clean foreign objects, dust, etc. in cables before coating operations, affecting the coating effect. Traditional integrated robots cannot balance weight and material capacity, and the large weight makes it impossible for robots to operate on thin diameter cables; The small adhesive load results in the need to supplement insulation coatings multiple times during coating operations with larger diameters or spans. Design purpose: To develop an intelligent cable insulation transformation equipment that is convenient to carry and can quickly assemble, flexibly adjust the adhesive load, and support functional expansion according to specific requirements for insulation and coating of overhead exposed wires. This product adopts a modular design approach, decomposing the robot into motion components, coating supply components, wrapping control components, cable cleaning components, control components, and battery components. The modules have high cohesion and low coupling, supporting rapid replacement. Robots can carry insulation coatings along overhead bare wires, inspect and clean the surface of the cables, and evenly coat the insulation coatings on the overhead bare wires, improving the insulation and anti-corrosion effects of overhead lines, enhancing the ability to resist harsh natural environments, and ensuring the safety of power transmission.The robot adopts a modular design and can be divided into six components: walking component, coating supply component, wrapping component, cleaning component, main control unit component, and power component. Improve the overall functionality of the robot through modular design. (1) Module expansion: Support performance and function expansion. For wrapping tasks with thick wire diameters or large spans, the expansion of double material barrels can be achieved by pulling and inserting them simultaneously. Support the flexible addition of cable cleaning components, infrared detection components, and other extension components according to job requirements to complete more job tasks. (2) Modular assembly: convenient for transportation. Modular design allows equipment to be disassembled and carried during transportation, resulting in a smaller volume and better protection of important components. (3) Modular hardware and battery components: easy to maintain. For faulty components, they can be quickly replaced, reducing maintenance time and greatly improving the usability of the robot. Through toolless design, the overall operability of the robot is improved: the design of sliding slots and positioning pins is used between various functional components, allowing for quick disassembly and assembly of components without the need for any tools. In terms of structure, in order to ensure stable EMC Functional requirement, all boards are concentrated in the main control unit components in combination with the modular design idea. Compared to the previous generation products, the usage of shielding metal plates has been reduced, resulting in an overall weight reduction of 0.8Kg. The coating supply component adopts an integrated sleeve assembly scheme, reducing the number of shell parts and simplifying the assembly process. By improving the design and optimizing the assembly process, the shell assembly process time was reduced from 4 hours to 2 hours, and the efficiency was increased by 50%.The core design concept of the insulated coating robot is precision simplification and toolization. Focus on creating a lightweight, user-friendly, reliable and stable user experience. The overall smooth and powerful contour reflects a sense of power; The large surface design has a strong overall sense, reflecting stability and reliability; The directional and rhythmic lines indicate the direction and speed of the product. In terms of color matching, the device adopts a main black with silver color scheme. Black is more rigorous and stable, and can better blend with the wrapped black insulated cable to form a unified visual experience. The auxiliary color is silver, which has a more industrial and technological feel, and can correspond with the colors of uncoated cables and iron towers. The design of nested color separation positions makes the product more layered.Bird pattern is an important type of traditional decorative pattern in China, widely used in porcelain and bronze, symbolizing auspiciousness and auspiciousness. By abstracting and integrating traditional bronze bird patterns, combined with modern design language expressions, the robot is designed as a flying bird with wings spread high. The head is summarized as a forward angular discount, and the tail is designed as an asymptotic double line that rises upwards. The walking component uses an asymptotic double line to outline the unfolded wings of a bird. When robots perform cable operations at high altitudes, they are like mechanical birds that better integrate into the natural environment, while also reflecting the organic combination of modern technology and traditional culture.The equipment adopts modular design, and in order to facilitate on-site assembly and disassembly, toolless design is adopted between each module, eliminating the dependence of operation on tools, simplifying the assembly process, and improving work efficiency. The on-site operators can complete the assembly process of the entire equipment within 1 minute. Due to the fact that the equipment operation process is live working and the working object is a live line, the safety of the equipment is the primary factor. We have developed an autonomous online and offline function, where operators can remotely operate the online and offline platform through wireless means, eliminating the need for physical contact during the entire operation process and avoiding contact risks. For some areas where automatic loading and unloading cannot be used, we have conducted sufficient ergonomic analysis to meet the needs of manual lifting for online use. We have designed a dual handle scheme for upper and lower operations, which is convenient for both hands. The lower handle is convenient for lifting and applying force, and the elbow joint can be supported on the trunk to further disperse the force, providing about 75% of the support force during the operation process; The upper handle provides upward pulling force and maintains direction and angle. The upper handle is designed with adhesive wrap, providing insulation and anti slip effects while ensuring a comfortable grip.