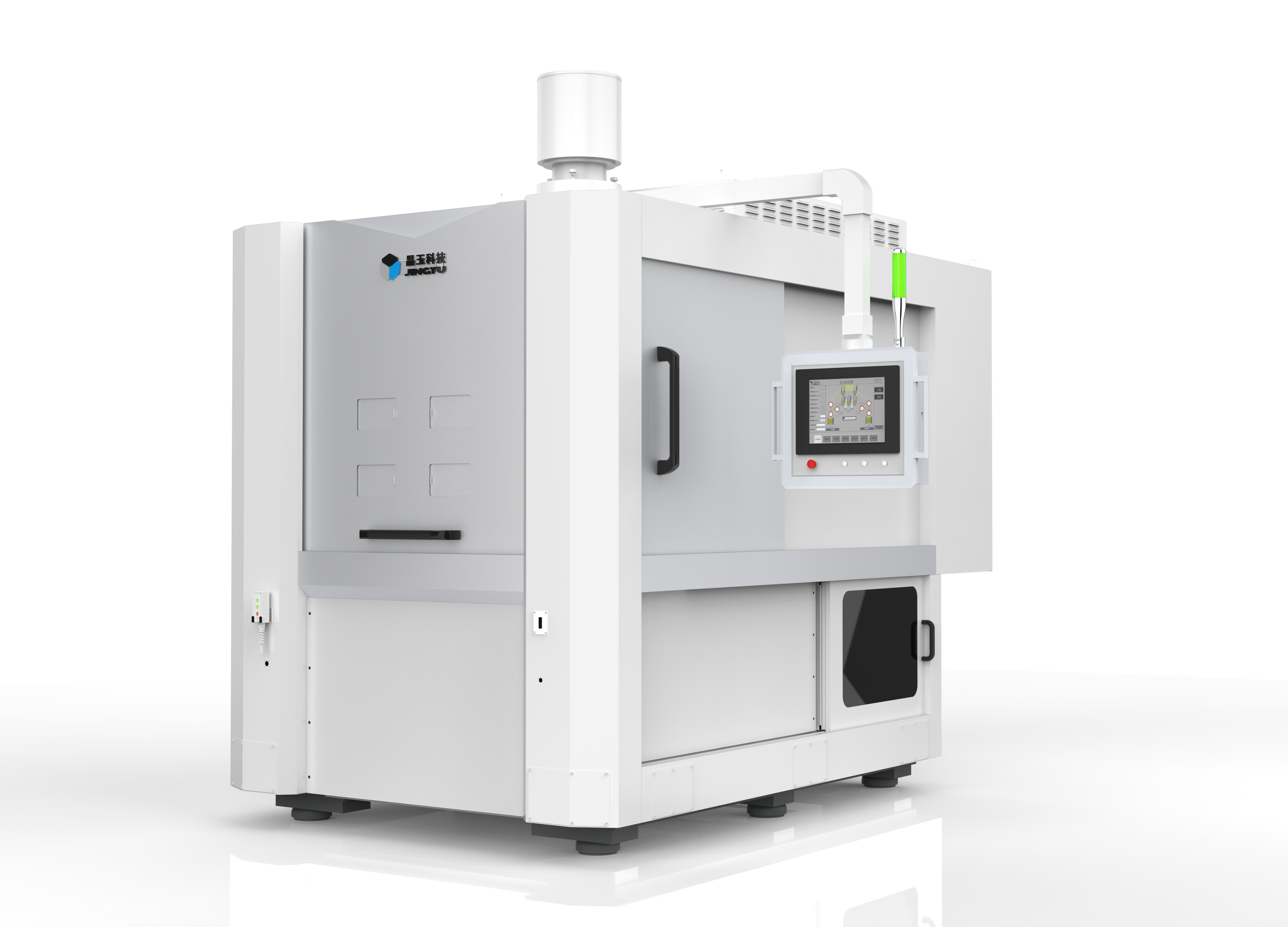

SDX16100 Double Station Multi Wire Saw

Brand Name:唐山晶玉科技股份有限公司

Design Company Name:唐山晶玉科技股份有限公司

Nationality / Region:China

Entry ID:2024-04-1554455

Entry Category:Product_Group

Categories:Manufacturing Equipment

Introduction

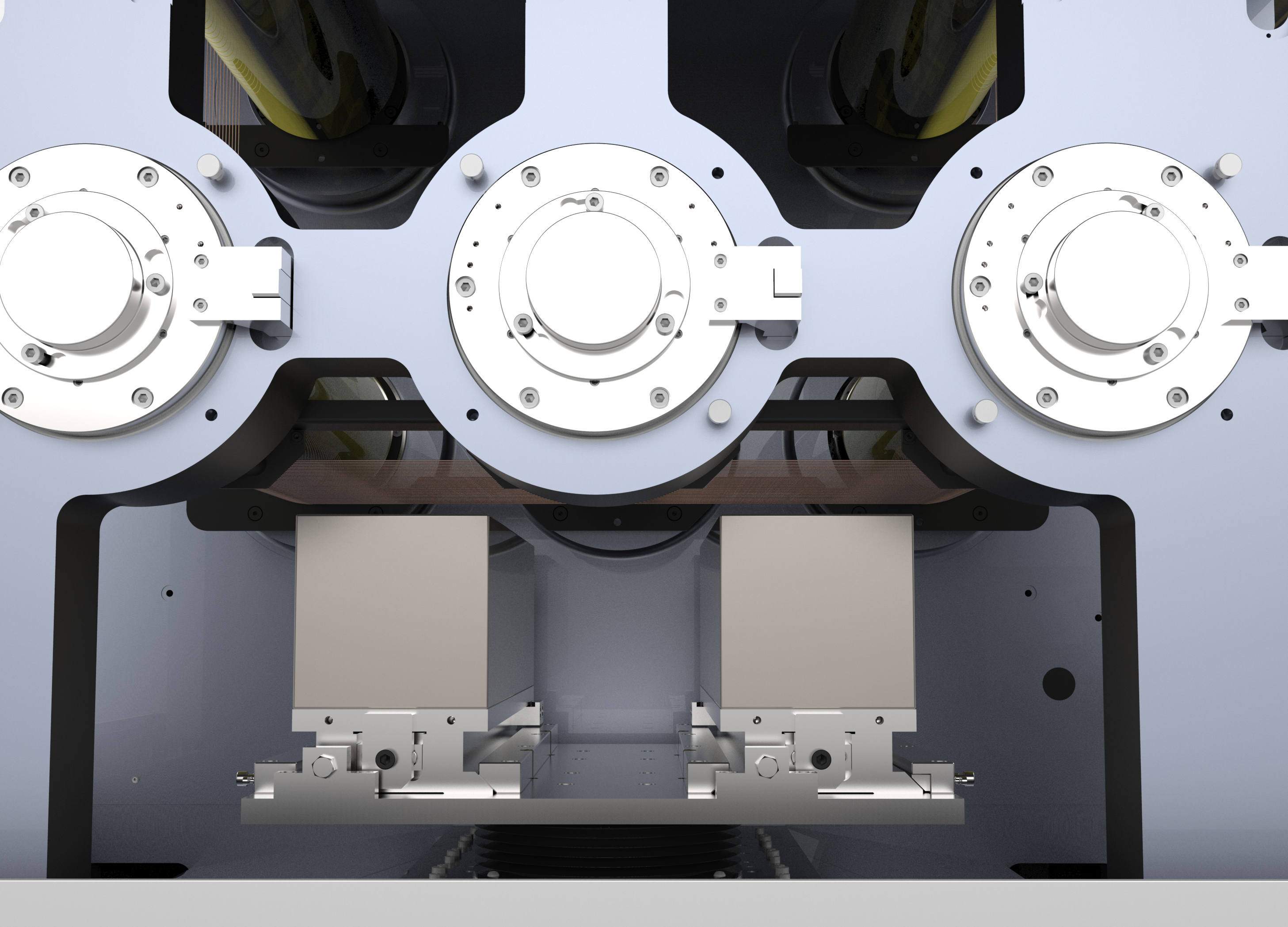

Multi wire saw is usually a parallel steel wire mesh wound on two grooves, forming a cutting area between the two grooves. During the cutting process, the steel wire mesh moves back and forth, and the workpiece to be processed is lifted and lowered on the workbench to achieve multi wire cutting. Due to the fact that multi wire cutting is a flexible cutting method, the actual steel wire will undergo flexible deformation, causing wire bows, especially in large wheelbase cutting operations, which can easily cause steel wire shaking during cutting, affecting product quality and cutting efficiency.SDX16100 double station multi wire saw is a traditional multi wire saw that adds a spindle groove wheel to form two cutting areas. By reducing the wheelbase, it increases the stability of the cutting wire network. Innovate double workstation design to fill industry gaps. The maximum cutting width is 160 × 1000mm × 2 plates, with wire speed of 2600m/min and a machining accuracy of 0.01mm. It can achieve high wire speed non grinding cutting technology, save subsequent grinding processing costs, and improve machining efficiency by more than 30%.The appearance design continues the Products Identity System, ensuring the family identity of the enterprise's products and forming effective brand recognition through accumulation. The clever combination of function and form beauty makes the product more practical and aesthetically pleasing. Simple lines and proportional segmentation can better highlight the industry characteristics of precision cutting of products.The product meets the needs of customers for efficient and high-quality cutting, while reducing material waste and saving energy, in line with the cultural concept of green and sustainable development. Its launch and application have promoted the progress of processing technology for hard and brittle materials, as well as the development of application industries such as rare earth permanent magnets, semiconductors, and photovoltaics.The product uses diamond wire cutting and water-based emulsion lubrication, and the cutting process does not produce pollutants such as dust and exhaust gas, which is harmless to the environment. Equipped with servo bus control technology, it responds quickly and has a user-friendly human-machine interaction interface, which is simple, clear, and easy to understand. The working status is clear at a glance, making it easy to operate.